Product details

Features

Composition

Polyurethane

Application time

20 seconds

Thickness

350 microns

Application temperature

160°C

Peeling

Cold

- Washing - 40°C, Hand wash

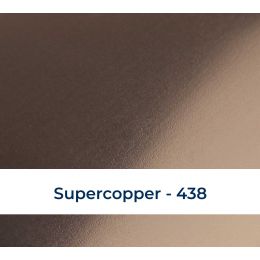

- Specific effect - Glittering

- Textile compatibility - Cotton, Polyester, Polycotton, Acrylic

- Ironing - On reverse only

Avis

Sort reviews by :

Anonymous A. the 06/09/2022 :

Bon produit