Product details

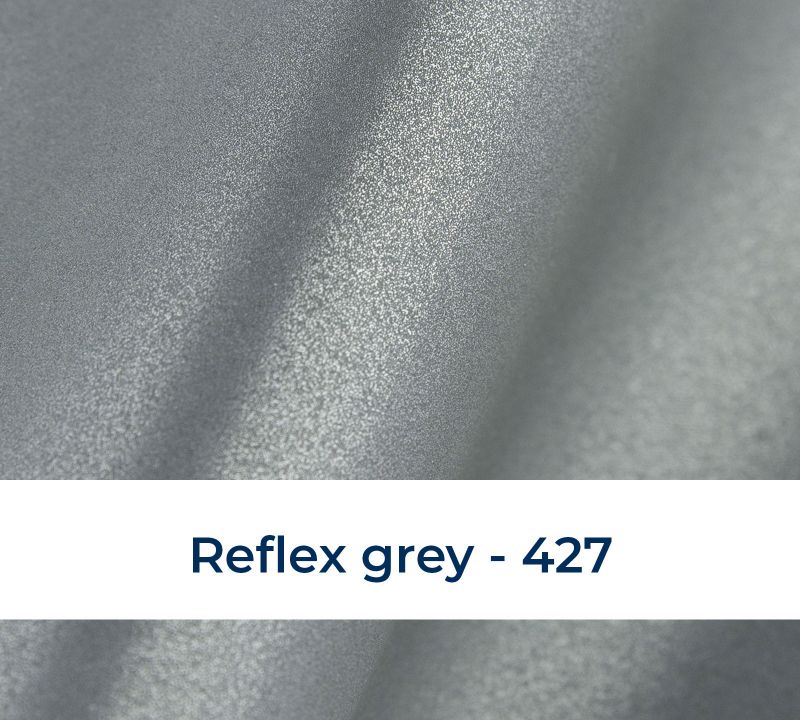

Reflective polyurethane film for heat transfer on cotton, polyester, acrylic and similar fibers.

This product has the property of reflecting light. Reference 427 is used for all safety clothing thanks to standard EN ISO 20471.

This standard defines the quantity of restored light reflected by the support.

Features

Composition

Polyurethane

Application time

15 seconds, 20 seconds, 10 seconds

Thickness

150 microns, 200 microns

Application temperature

160°C

Peeling

Hot or Cold

- Washing - 40°C, 60°C

- Specific effect - Reflective

- Textile compatibility - Cotton, Polyester, Polycotton, Acrylic

- Certifications - ISO standards, Vegan

- Ironing - On reverse only

Application Instructions

- Cut the film in mirror mode with a flex blade, optimizing the blade setting.

- Weed the excess material.

- Position and press the marking on the textile with its polyester support, protecting it with siliconized paper.

- 1st pressing: 160 ° C - 3 seconds - Medium pressure (remove the polyester after pressing)

- 2nd pressing: 160 ° C - 15 seconds - Medium pressure - Remove hot polyester.

Care & Maintenance Recommendations

- Observe the instructions specified on the clothing

- Wait 24 hours before the first wash

- Iron inside out only

- Storage: maximum 1 year, vertically and protected from light and humidity

- Washing: maximum 40 ° C inside out

- Do not use aggressive products (bleach, etc.)

- Tumble dryer: Yes

- Dry cleaning: Yes

Avis

Sort reviews by :

Anonymous A. the 06/04/2022 :

Comme annoncé

Anonymous A. the 09/04/2021 :

Flex de bonne qualité