Product details

Features

Composition

Polyurethane

Application time

20 seconds

Thickness

50 microns

Application temperature

160°C

Peeling

Cold

- Washing - 60°C

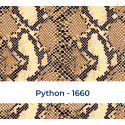

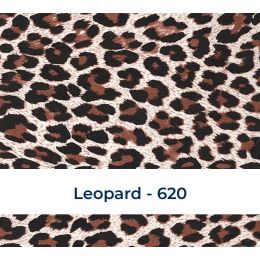

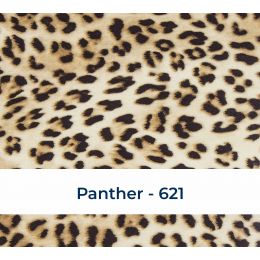

- Specific effect - Patterned

- Textile compatibility - Cotton, Polyester, Polycotton, Acrylic

- Certifications - Vegan

- Ironing - On reverse only

Avis

Sort reviews by :

Isabelle A. the 25/07/2023 :

Bonjour .c est hyper joli.je n ai pas encore essayé.

Melanie L. the 12/04/2023 :

Petit motif sympa

Estelle C. the 08/11/2022 :

Sympa, conforme à la photo

Anonymous A. the 09/08/2022 :

pas encore testé

Anonymous A. the 28/07/2022 :

Très beau rendu conforme à l'image