Textile marking glossary

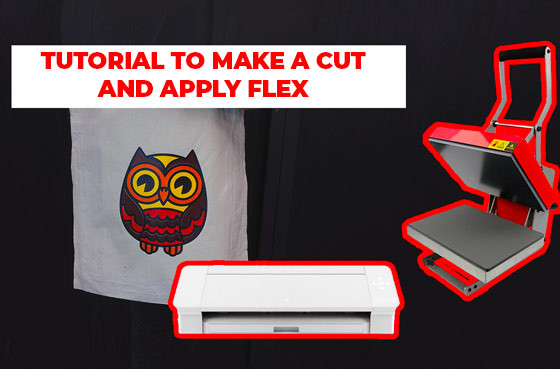

High quality polyurethane or vinyl film used in textile marking. The flex has the property of being heat-weldable and is transferred using a heat press. It is cut using a cutting machine called a "plotter". This film is available in an infinite panel of colors with different thicknesses, textures, aspects and dimensions.

Viscose film used in the field of textile marking which has the property of being heat-sealable and transferable using a heat press. The flock is cut using a cutting machine called a "plotter". It differs from flex by its “velvet” appearance and feel as well as its covering power and its more or less long fibers.

Film used in the field of signage to personalize all types of media, smooth or curved, interior or exterior. Thanks to this adhesive film, you can personalize your mugs, cars, windows, etc ...

Method which makes it possible to "stick" the flocking on the fabric support, cap, various textile supports, etc ... Secondly, it suffices to gently remove (cold or hot according to the characteristics of the product) the surplus of useless material for let appear the desired pattern or logo.

Technique which allows the personalization in one color of both textile supports. The transfer takes place by the action of pressing and heat on the support which becomes permanent. This process is particularly suitable for small and medium series. It is mainly used for numbering and marking T-shirts, sportswear, caps, bags, etc.

A printing technique that uses screens interposed between the ink and the medium. You don't need to have a flat surface to screen print. It allows a large quantity production once the preparation of the different frames of each color has been completed. Screen printing is for any type of personalization by object on plates, mugs, pens, etc.

Computer-controlled sheet or roll cutting machine. Using drawing software supplied with the machine, you can draw your logo, pattern, design, text, etc. or choose from the examples in the library. Once vectorized in the software, the machine will automatically recognize the lines and start cutting. Possibility to cut flex, flock, plastic, paper, cardboard, fabric, etc ...

Machine with heating plate, the temperature, pressure and duration of which can be adjusted. In the case of transfer, this machine will melt the glue and will fix the marking on the textile support. For sublimation, she will fix the inks on the support.

Common name for determining the heat transfer of a film. Previously, flocking was one of the only methods used by screen printers. Then, with the advent of cutting plotters, flex and flock films appeared on the market. The flocking has a soft feel which is much appreciated.

A marking technique that involves passing the inks directly from the solid state to the gaseous state. From a sublimation ink printer, the logo or design is reproduced directly on a special transfer paper or can be printed directly on the appropriate transfer paper. By the action of heat, the ink changes from a solid state to a gas state and then returns to a solid state by attaching to the polyester support. Sublimation has many advantages.

Additional specific treatment which consists of adding a layer of varnish to the product to promote printing.

Operation which follows the cutting phase and which consists in removing the excess unnecessary material overflowing or inside the outline of your pattern, logo, number, etc ... This phase being meticulous, you can use a pliers or a hook weeder for the precision of small details.

Action which consists in removing the carrier polyester film after pressing. This can be done immediately after the press run in the case of a "hot peel" recommendation. For other products, it is recommended to peel only when the product has completely cooled: "cold peel".

Adhesive film, transparent on a polyester base or opaque on a paper base, which is used to transfer, after cutting with a plotter, a marking or drawing in order to re-deposit it on the final textile support. Can also be used for signage and the installation of adhesive vinyl on windows, cars, furniture, etc.

Using graphic design software, you draw or choose your logo which will be the vector pattern for your future cutout. The cut must be made in a mirror mode because, during pressing, you will have to turn your cut over to put the part to be transferred against the textile support and the protective polyester film on top.

Adhesive sheet on which the flex is positioned before passing through the cutting plotter. This support allows to maintain the flex during cutting so as not to move. This sheet also makes it possible to work with product scraps to avoid losses. The cutting plotter can also be used without the carrier sheet, directly with product packaged in reels.

Very resistant adhesive plastic strip which protects the blade during cutting with a plotter. With use, this Teflon tape can be damaged due to improper blade settings. Do not hesitate to change this Teflon tape from time to time.

Canvas used to protect the lower or upper plates of heat presses. This canvas can be changed in the event of damage during use of the press, (glue deposit ...).

Plastic film that sits on top of the flex. This support makes it possible to transfer the flex once cut directly onto the final textile support. This polyester film will also protect the marking during the press process. Once the pressing is done, it is this film that we will "peel" cold or hot depending on the characteristics of the product.

100% secure

payment

Fast delivery

from 24 to 72H*

*Depending on the carrier

Customer service at

+33 9 67 04 74 21

Certifications

Oeko-Tex and EVE Vegan